Customer – Mr. DIY

It is a part of MR D.I.Y. Group Berhad, and provides home improvement products for do-it-yourself projects through online and offline stores.

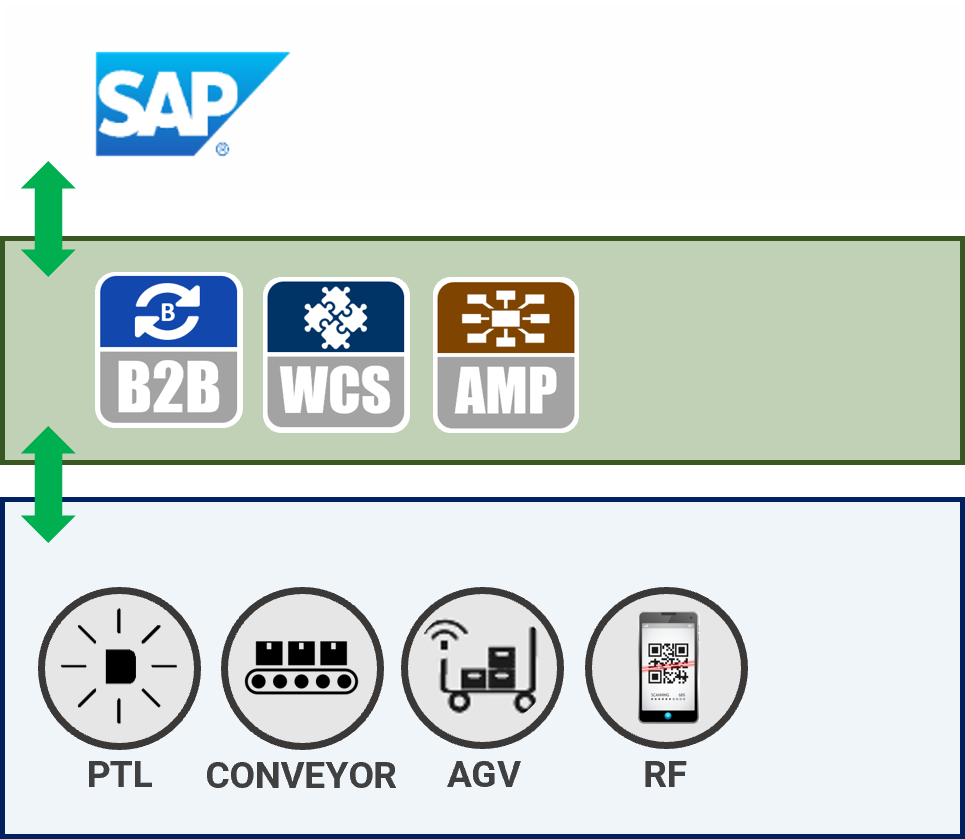

Solution

To provide Infolog WCS and Automation Middleware that act as the bridge between Mr. DIY ERP system to the operation execution system with AGV, conveyor system, RF Devices and Pick To Light solution

Benefits

+ Increased productivity by 300%

+ Triple labor picking rate up to 600 pcs/hour

+ Reduced labour costs by 40%

+ Rapid deployment (3 months)

+ Increased picking accuracy to 99.99%

+ 94% reduction in workforce turnover through upskilling

+ Up to 500% or more improvement in storage density

+ Rapid ROI <2 years payback period

+ Lower production accident risk

Impact

To meet the throughput of 6,000 pcs per day, reduce the workforce in warehouse operation for online order fulfillment and optimize the footprint of the existing warehouse